Home > Mask Manufacturing > Photo Mask

Through the supply of "photo masks" which are used as original plates in "photolithography" [*1],

Mitani Micronics has contributed to the development of high-precision and high-definition products

such as various kinds of electronic components which support the next generation applications,

microdevices including semiconductors (semiconductor package, power device, etc. [*2]),

diverse substrates (multilayer substrate, device embedded substrate, bumped substrate, etc.) and

displays (liquid crystal display, organic EL display, FPD, touch panel display, etc.).

- *1 : One of the microfabrication techniques. Using a photo mask as an original plate, forms mainly an electronic circuit pattern by photosensitive resin application, exposure, development and etching.

- *2 : quartz crystal device, MEMS product, LED product, electronic paper, touch panel

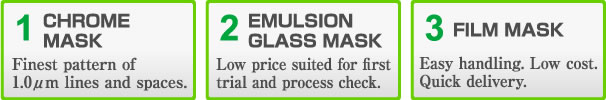

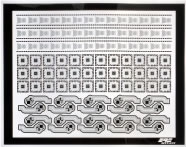

The following two types of photo masks are available:

We offer a photo mask as a calibration mask for exposure, measurement and alignment of a manufacturing equipment.

- *3 : "Calibration" means measurement adjustment・equipment adjustment.

Plotting System Correspondence Table

Generally, a chrome mask has two main types of base materials: soda lime glass which is comparatively inexpensive and synthetic quartz which has low thermal expansion and high optical transmittance.

Beside the above, there are masks with special base materials (Pyrex, BK7, Tempax, etc.).

Chrome Mask Material Characteristics Graph

Glass Characteristics Table

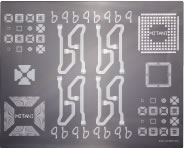

A film mask uses PET film as base material.

The film composition and production process follow traditional photographic processes such as exposure, development and fixing.

It is elastic depending on the usage environment (temperature and humidity) due to the nature of the base material.

For uses which require fineness and position accuracy, or overlay accuracy, we recommend the use of a glass mask.

1. Pellicle-Covered Photo Mask (one side/both sides)

When introducing a projection exposure system, please consider using a pellicle-covered photo mask which reduces yield decrease due to foreign particles.

*Please consult with us about pellicle (type, size, etc.).

2 . Photo Mask (glass) External Shape Machining

Please consult with us about machinable shape (concavity and convexity, groove, hole, etc.), size, etc.

3 . Clean Room (class 100, class 1000)

Temperature 22℃±1℃ Humidity 50% RH±10%

4 . Photo Mask Material List

We can also make masks of size or material not listed below.

5 . Pattern repeatability variation among different plotting machines and modes (in-house comparison).